Diffraction Measurements

A report on practical EN 1793-4 / EN 16272-4 measurements

In this report we will look at an example of practical measurements performed in March 2025 together with a team from 4Silence. 4Silence is a Dutch company specializing in noise barriers based on diffraction principles.

We were very grateful to be given the opportunity to perform detailed measurements at a real-world site, together with expert help from Julio Hermes of 4Silence. It gave us the opportunity to field-test the new MA 25 microphone array, and the new ZIRCON software. At the same time, it gave 4Silence the opportunity to validate their noise barrier design with high-quality measurements.

The site is located near the 4Silence offices at Twente airfield and consists of a 4 m high and 12 m long concrete barrier segment with the diffractor mounted on top.

The site was relatively quiet, even though there were some background noises, such as a tractor ploughing a nearby field,

and the airport fire department conducting a chemical hazard exercise. None of these had any effect on the measurements however.

The wind speed was well below 4 m/s and there was no precipitation.

We used the following equipment:

- ZIRCON 1.0 software

- MA25 microphone array with ET24 extender tube

- LS24 loudspeaker source with TH24 tilt head and ET24 extender tube

- CI24 control interface

- Measuring tape and laser-based distance meter

- A Windows PC

- Bresser Portable Power Supply 500 Watt and approx. 500 Wh

Pictured above are the barrier with the diffractor mounted on top, and the MA25 array and LS24 loudspeaker unit positioned for a free-field measurement.

Note that the MA25 array and LS24 loudspeaker unit are raised 4 m above the ground, which makes horizontally positioning the tripods somewhat challenging. The LS24 in particular, should best be positioned by two people to make sure it doesn't topple over. Note also that the cables should be flat on the floor and fastened as close to the ground as possible to the tripod legs, to prevent tripping hazards.

The first set of 4 measurements was made with the diffractor installed.

Strictly speaking, each of the 4 (source) positions requires a certain source elevation to point the source to microphone 1, being 14, 9, 10 and 7 degrees respectively. However, due to the great height of the source, changing the elevation would require quite a bit of effort. From the (favourable) directional characteristic of the LS24, it can be calculated that a fixed average elevation of 10 degrees results in a negligible worst-case error in the order of 0.1 dB, so the elevation was chosen 10 degrees for all positions.

Given the specified heights of the various construction elements, such as the ET24 extender tubes (1.50 m), the MA25 array (0.99 m from mounting plane to centre mic) and the LS24 loudspeaker source (0.125 m from mounting plane to LS centre), it is easy to derive the required tripod mounting plane height from the total height. This enabled us to omit direct and difficult full height measurements. We also used the scale on the tripod central tubes, for relative changes.

Although we found a few minor problems in the first version of the ZIRCON software, we were able to complete the measurements without any issues. The MA25 array worked very well, and the new ZIRCON software made it easy to set up and perform the measurements. The measurements were performed in accordance with EN 1793-4 / EN 16272-4, using an exponential sweep covering the 125 Hz to 8 kHz octave bands. The sweep duration was 2.7 seconds, and 16 sweeps were averaged per measurement position.

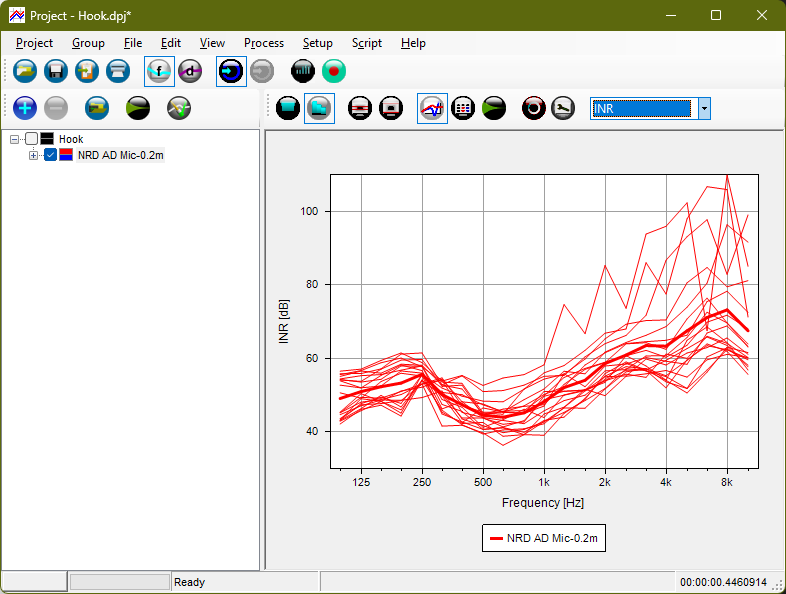

The INR (Impulse Response to Noise) values were excellent, as was to be expected for a diffraction measurement.

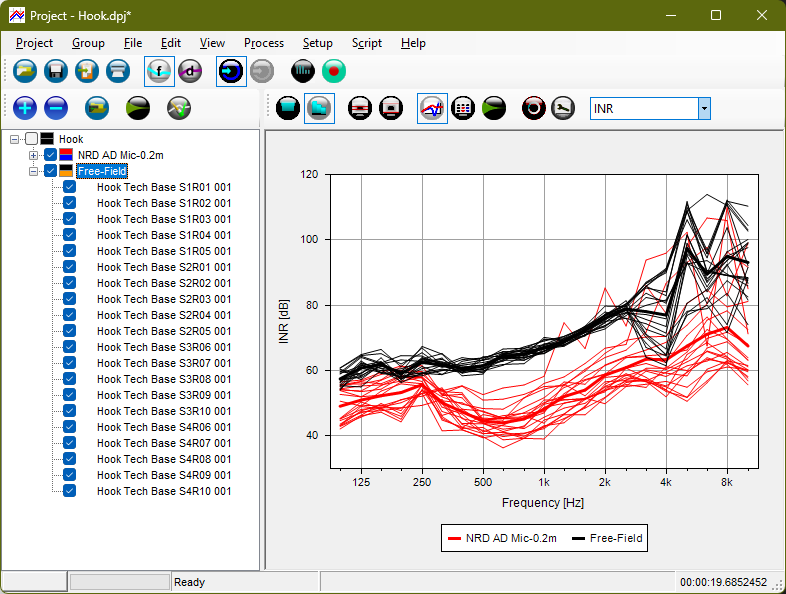

We then proceeded with the free-field measurements, resulting in 4x5 individual IRs with even higher INR values:

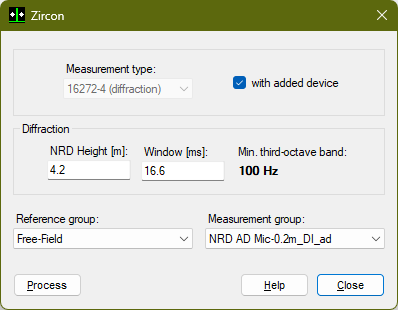

Using both sets of measurements (NRD with diffractor and Free-field) we can set up the diffraction calculations using the (Process-) Zircon dialog:

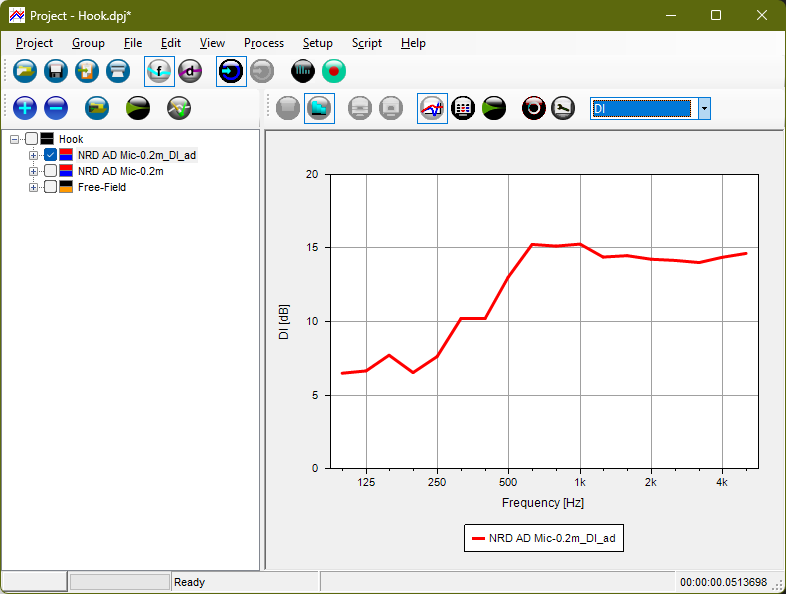

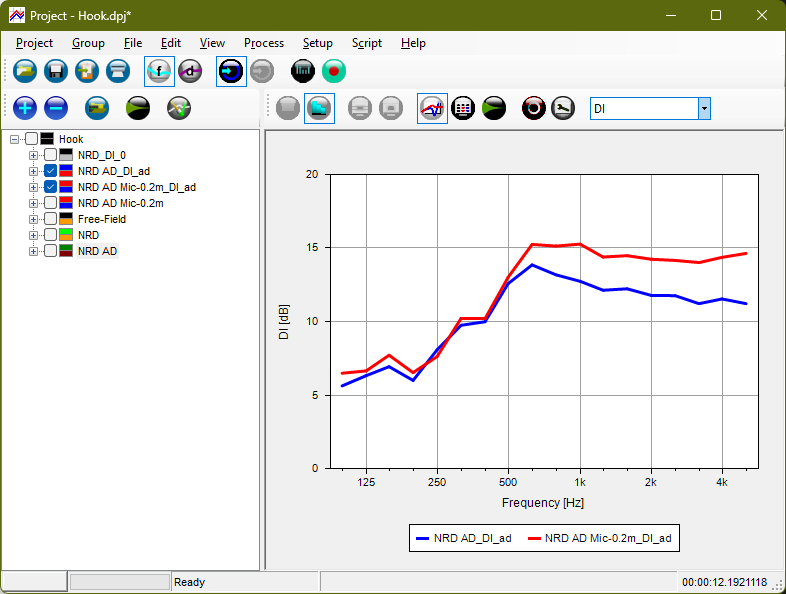

The resulting DI (Diffraction Index) values can be seen below:

To measure the diffraction index of the barrier without added device, the diffractor had to be removed. Fortunately, 4Silence had the specialized equipment to do just that.

With the diffractors safely set aside, we could continue our measurements.

While setting up the MA25 microphone array, we noticed an earlier mistake in the array position. It seemed we had failed to take the 20 cm diffractor height into account, and the array was positioned 20 cm too low in the first set of measurements with the diffractor on top of the NRD. The lesson learned here is to double or triple check the measurement geometry.

A detailed checklist for all the steps to be performed for the complete set of measurements is essential. The checklist should include all the equipment that is needed for the measurements, and the procedures for how to position the source and microphone position with respect to the NRD and each other. Such a checklist should eventually be based on practical user experience, but could start from TN019:

TN019 - EN 1793-4 and EN 16272-4 Measurement Procedure

A small table and chairs will add extra comfort during the measurements.

Protective suits for chemical hazard are usually not required for diffraction measurements.

Airport fire department conducting a chemical hazard exercise in the neighbourhood

Thus, we performed barrier measurements without diffractor, and the good people from 4Silence were willing to re-install the diffractor so that we could repeat the diffractor measurements at the correct height.

The difference in the DI spectrum for the initial and the corrected measurements were significant.

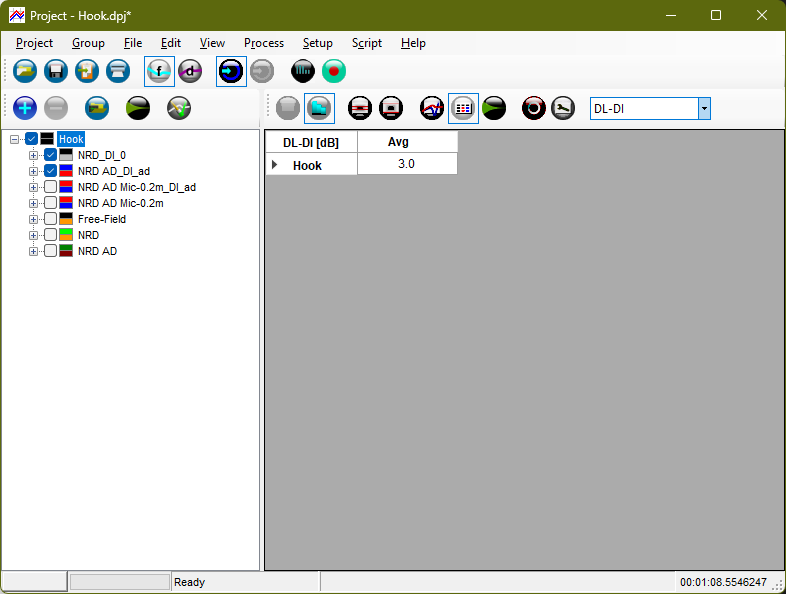

Based on the correct measurement we can calculate the Sound Diffraction Rating DLDI.

The complete session took some 3 hours, but that included an erroneous measurement. We hope to soon have an opportunity to repeat these measurements, together with 4Silence. In the next session there is the intention to also measure the diffractor rotated by 180°. It will be interesting to get an indication of the repeatability of the DI measurements.